1. Accumulating more than 20 years of professional manufacturing experience, SHANGHAI COREWIRE INDUSTRY CO., LTD. Specialized in supplying TM-12~273 ERW tube mill machine efforts quality improvement and technological researching. 2. Meanwhile, the R&D center featured The ERW tube mill with high-strength design, material selection, precision machining, stable operation, and energy conservation.

1. Accumulating more than 20 years of professional manufacturing experience, SHANGHAI COREWIRE INDUSTRY CO., LTD. Specialized in supplying TM-12~273 ERW tube mill machine efforts quality improvement and technological researching. 2. Meanwhile, the R&D center featured The ERW tube mill with high-strength design, material selection, precision machining, stable operation, and energy conservation. The products are mainly pipes and tubes used in petroleum, petrochemical, construction, shipbuilding, military, electric power, mining, coal, machinery manufacturing industries.

The products are mainly pipes and tubes used in petroleum, petrochemical, construction, shipbuilding, military, electric power, mining, coal, machinery manufacturing industries.

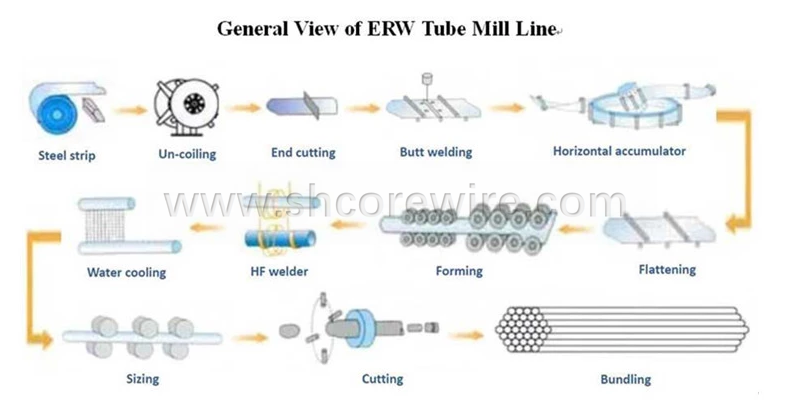

This TM-32 ERW Tube & Pipe Mill, complete with un-coiler & strip-head shearer & butt welder station & forming mill & sizing mill & cold flying saw & conveyor table & stacking & packing machine. The optimized design, high-quality material selection, and strict heat treatment process guarantee the high precision, wear-resisting, and long life of the roller.

This TM-32 ERW Tube & Pipe Mill, complete with un-coiler & strip-head shearer & butt welder station & forming mill & sizing mill & cold flying saw & conveyor table & stacking & packing machine. The optimized design, high-quality material selection, and strict heat treatment process guarantee the high precision, wear-resisting, and long life of the roller.| Model | Tube O.D (mm) | Wall Thickness (mm) | Square/Rectangle (a:b≤ 2:1,mm) | Wall Thickness (mm) | Speed (m/min) | Main motor (KW) | H.F.Welder (KW) |

| TM-12 | φ4~φ12 | 0.2~0.5 | // | // | 30~120 | 15 | 100 |

| TM-16 | φ6~φ16 | 0.2~0.8 | // | // | 30~120 | 22 | 100 |

| TM-20 | φ7~φ20 | 0.2~1.0 | // | // | 30~120 | 30 | 100 |

| TM-25 | φ9~φ25.4 | 0.25~1.2 | // | // | 30~120 | 37(or22*2) | 100 |

| TM-32 | φ10~φ32 | 0.25~1.5 | 8*8~25.4*25.4 10*6~31.8*19.1 | 0.25~1.2 | 30~120 | 45(or 30*2) | 100 |

| TM-32z | 0.5~2.0 | 0.5~1.5 | 30~100 | 55(or 37*2) | 100 | ||

| TM-40 | φ12.7~φ40 | 0.3~1.8 | 10*10~31.8*31.8 20*10~40*20 | 0.3~1.5 | 30~110 | 75 | 150 |

| TM-40z | 0.6~2.0 | 0.6~1.5 | 30~100 | 45*2 | 150 | ||

| TM-50q | φ16~φ50.8 | 0.4~1.5 | 12.7*12.7~40*40 20*10~50*25 | 0.4~1.2 | 30~110 | 90 | 150 |

| TM-50 | 0.5~2.0 | 0.5~1.5 | 30~90 | 45*2(or 110) | 200 | ||

| TM-50z | 0.7~2.5 | 0.7~2.0 | 30~80 | 55*2 | 200 | ||

| TM-63q | φ19.05~φ63.5 | 0.6~2.0 | 15*15~50*50 20*10~60*30 | 0.6~1.5 | 30~90 | 132(or 55*2) | 150 |

| TM-63 | 0.7~3.0 | 0.7~2.5 | 30~80 | 75*2(or 132) | 200 | ||

| TM-63z | 0.8~3.5 | 0.8~3.0 | 20~70 | 90*2 | 200 | ||

| TM-76q | φ25.4~φ76.2 | 0.8~2.5 | 20*20~60*60 30*15~80*40 | 0.8~2.0 | 30~90 | 160(or 75*2) | 200 |

| TM-76 | 0.8~3.5 | 0.8~3.0 | 30~80 | 90*2 | 250 | ||

| TM-76z | 0.8~4.0 | 0.8~3.5 | 20~70 | 300 | |||

| TM-90q | φ30~φ90 | 0.8~3.0 | 25*25~70*70 30*20~80*40 | 0.8~2.5 | 30~90 | 180(or 90*2) | 250 |

| TM-90 | 0.8~3.5 | 0.8~3.0 | 30~80 | 110*2 (or 132*2) | 250 | ||

| TM-90z | 1.0~4.0 | 1.0~3.5 | 20~70 | 300 |

| Model | Tube O.D (mm) | Wall Thickness (mm) | Square/Rectangle (a:b≤ 2:1,mm) | Wall Thickness (mm) | Speed (m/min) | Main motor (KW) | H.F.Welder (KW) |

| TM-100q | φ31.8~φ101.6 | 1.0~3.0 | 25*25~80*80 30*20~100*50 | 1.0~2.5 | 30~90 | 200(or 110*2) | 250 |

| TM-100 | 1.0~3.75 | 1.0~3.25 | 30~80 | 110*2 | 300 | ||

| TM-100z | 1.0~4.25 | 1.0~3.5 | 20~70 | 132*2 | 300 | ||

| TM-114q | φ35~φ114.3 | 1.0~3.0 | 30*30~90*90 40*20~120*60 | 1.0~2.5 | 20~80 | 110*2 | 300 |

| TM-114 | 1.2~4.5 | 1.2~4.0 | 20~70 | 132*2 | 350 | ||

| TM-114z | φ40~φ114.3 | 1.2~5.0 | 1.2~4.5 | 15~60 | 350 | ||

| TM-127q | φ40~φ127 | 1.2~3.5 | 40*40~100*100 60*30~120*80 | 1.2~3.0 | 20~70 | 132*2 | 350 |

| TM-127 | 1.5~5.0 | 1.5~4.5 | 15~60 | 160*2 | 400 | ||

| TM-127z | φ50~φ127 | 1.5~5.5 | 1.5~5.0 | 10~45 | 160*2 | 400 | |

| TM-140q | φ50~φ141.3 | 1.2~4.0 | 50*50~110*100 60*40~150*75 | 1.2~3.5 | 15~60 | 160*2 | 400 |

| TM-140 | 1.5~5.5 | 1.5~5.0 | 10~50 | 180*2 | 400 | ||

| TM-140z | φ60~φ141.3 | 2.0~6.0 | 2.0~5.5 | 10~40 | 180*2 | 500 | |

| TM-168q | φ60~φ168.3 | 1.5~5.0 | 60*60~130*130 80*40~160*80 | 1.5~4.5 | 10~50 | 180*2 | 400 |

| TM-168 | 2.0~6.0 | 2.0~5.5 | 10~50 | 200*2 | 500 | ||

| TM-168z | φ76.2~φ168.3 | 2.5~8.0 | 2.5~7.0 | 10~40 | 200+132*2 (or 132*4) | 600 | |

| TM-219q | φ89.1~φ219.1 | 2.0~6.0 | 70*70~160*160 100*50~200*100 | 2.0~5.5 | 10~50 | 110*2+110*2 | 500 |

| TM-219 | 3.0~8.0 | 3.0~7.0 | 10~40 | 132*2+132*2 | 600 | ||

| TM-219z | 4.0~10.0 | 4.0~9.0 | 10~40 | 132*2+160*2 | 800 | ||

| TM-273 | φ114.3~φ273 | 4.0~10.0 | 90*90~200*200 | 4.0~9.0 | 10~40 | 160*2+160*2 | 800 |

| TM-273z | 4.5~12.0 | 120*60~260*130 | 4.5~11.0 | 10~35 | 180*4 | 800 |

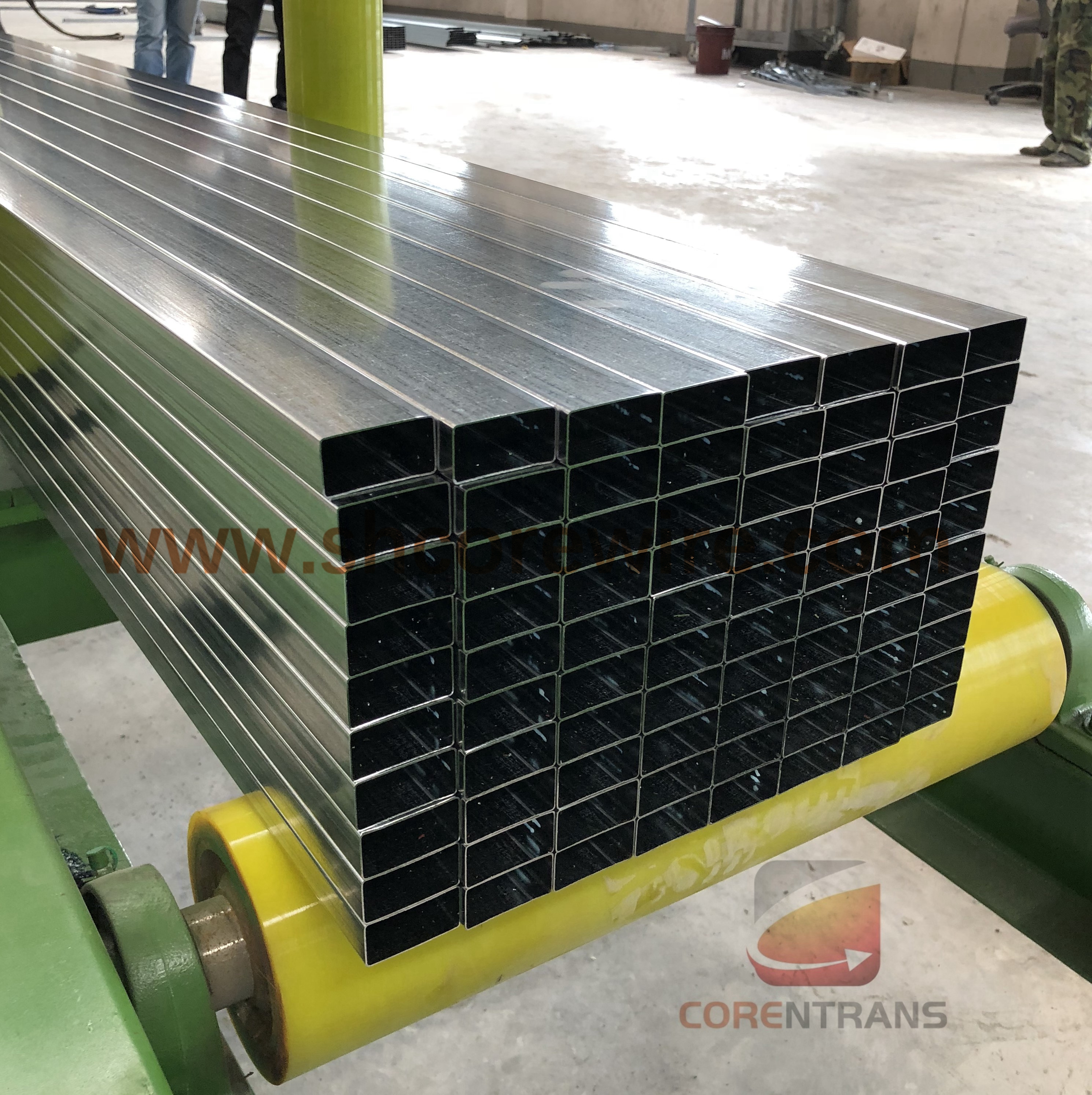

Application: The products are mainly pipes and tubes used in petroleum, petrochemical, construction, shipbuilding, car making, electric power, mining, coal, machinery manufacturing industries.

Application: The products are mainly pipes and tubes used in petroleum, petrochemical, construction, shipbuilding, car making, electric power, mining, coal, machinery manufacturing industries.